With extreme precision, we design and develop all the components in our watches. From thermally blued screws as small as a grain of sugar to solid gold watch cases weighing 70 grams. Each component is manufactured exactly to our designs and standards. We then bring all the parts together in our workshop to assemble a watch. Because we want only the best.

Some things should just be left as they are. No batteries, no notifications, no smart functions. Just some springs, gears and screws. There is nothing more magical than the refined ticking of a mechanical timepiece. You can stare at that for hours. All our watches are powered by timepieces of the highest standard. We develop our own parts that we add to existing timepieces. To make them more beautiful or to add extra functions.

It takes three days to make one Guilloche dial. But a handful of people manage to make one pink engine Guilloche dial. Each line is carved by hand. It is monk's work.

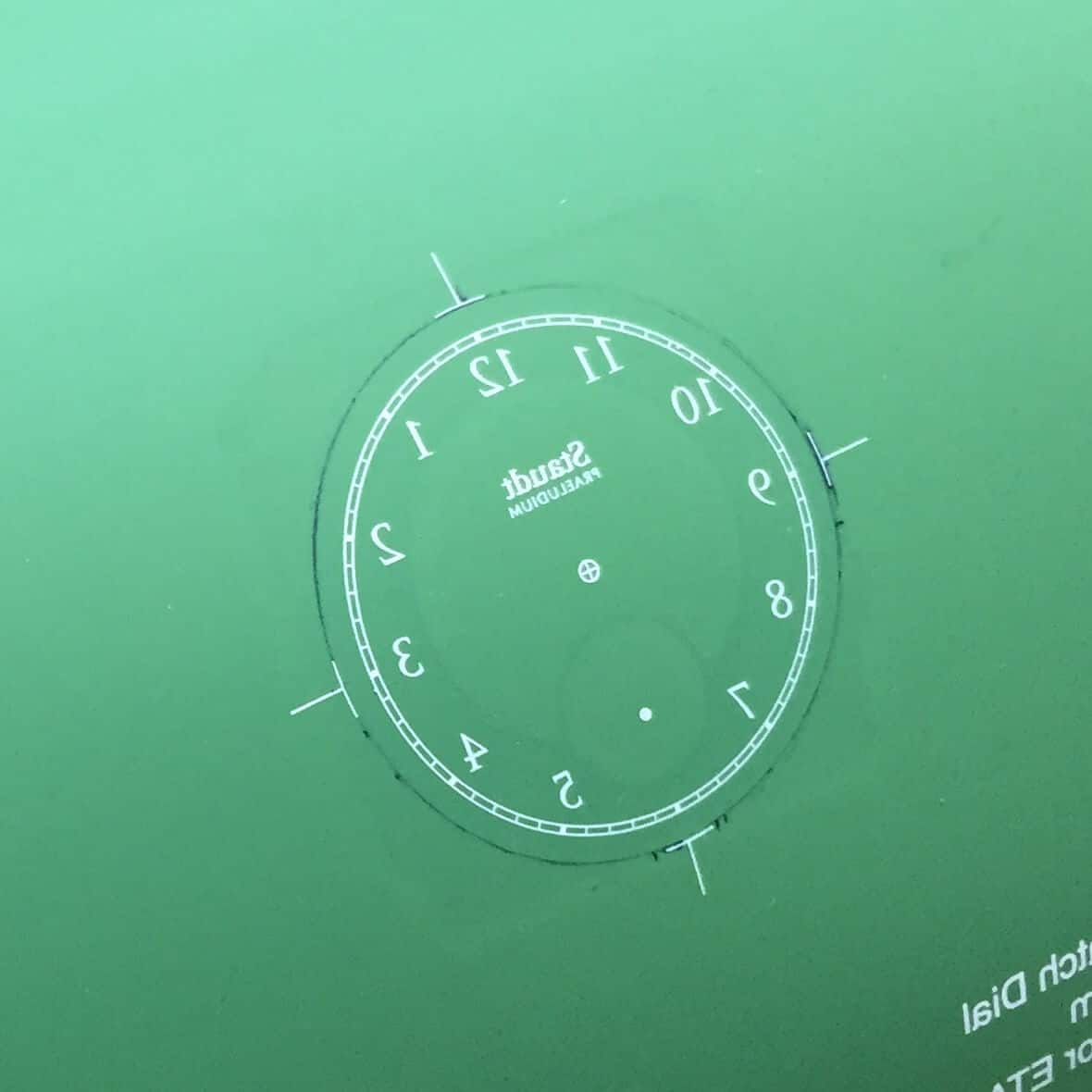

Staudt blue is unique. We use a special technique to create Staudt blue: lithography. This creates a special hue in the dial.

Every millimetre is a metre. To make the cases for our watches, we work closely with some of the best craftsmen in the industry. For our cases, we use 316L stainless steel or 18kt solid rose gold and they are finished by hand.

The choice is vast. We offer a wide range of watch straps. All straps are made in Italy from anti-allergic leather.